Hello to you all.....Here is a great project that we have been working on and nearing completion, its a restoration from a 1963 vw split screen van to a very nice ice cream van......this customer wants the best and WOW she is getting it, I have to undertake the re building of the original front single and double front seats.... including front door cards and cab area headlining. There is also a bespoke side canopy being made by myself as you will see.......hope you all like.

This is a picture of the bus with all the welding just been done and the process of making the body work under way.........

Here you can see the seat taking shape.....the center tuck and roll style going from front to back with the contrast outer panels sew on.......ready for the piping.

And there you go the piping sewing on......at this stage it is best to trial fit to the seat and test the fit.....

There you go......the side boarder sewn on in place....you can see the black marks from the old cover i transferred these over to the new material when cutting so it allows the lining up of the panels...........

This shot shows the base all cleaned and painted up ready for the cover to go on......always make sure the padding's are in good condition....if in doubt replace.........as the finished look will be only as good as the padding inside.............

This is the just come back from the painters look...........again a very important part to getting the end job to look good and last a long time..........

The finished seat..............as i always make sure the lines all match up and i think this very retro look is so great for this van.

A trial fit to see how they look and fit.......spot on.

A different angle....you can see the colours were chosen to match the outer van colour......cant wait to buy an ice cream of this van.............loll

Just a different picture showing the seats in place.

A step forward in time................all the windows in and trim on and almost ready, You can see the custom opening.... this is going to be the serving area..........

A better angle..you can see my custom frame work being made.......This is to finish the look of the van and to give the customers some cover if it rains............

A closer look ....you can see the bespoke arms made ....these can be removed when not in use......simple.....not !!!!! this took over 3 days to make and get to a finished part.

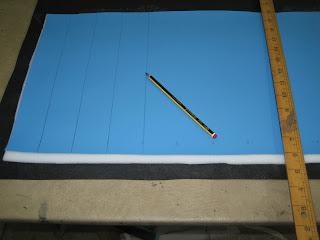

This is the template being fitted ,I use this as a pattern ...the same process as the seats........

.

The money shot......... As they say and Wow she look good.....

I hope you all liked the pictures look out for more projects to follow.If you need any help on your project just contact me on : 07794978914

cheers Colin.